What is Reflective Workwear and Why is it Important?

reflective workwear plays a crucial role in various industries, including construction and transportation. Experts emphasize its significance in ensuring worker safety. John Smith, a leading figure in the safety apparel industry, once stated, "Reflective workwear is not just clothing; it’s a lifeline." This highlights the vital function of these garments.

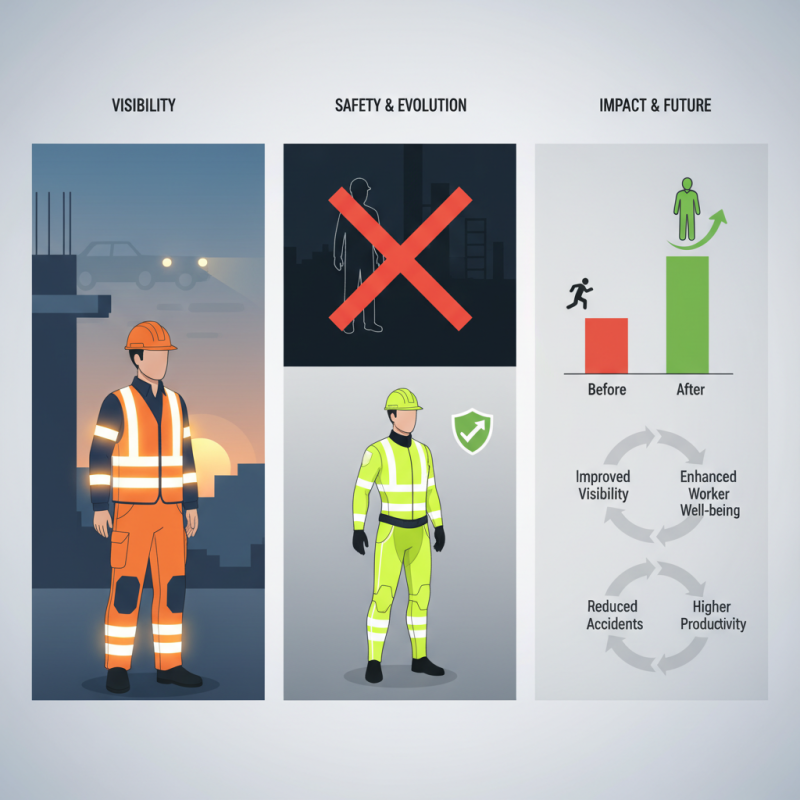

Visibility is a key aspect of reflective workwear. It helps workers stand out in low-light conditions. Imagine a construction site at dusk, where proper gear can prevent accidents. However, many industries still overlook compliance with safety regulations. This negligence can lead to tragic consequences.

Additionally, the design of reflective workwear has evolved. Modern garments combine functionality and comfort while maintaining visibility. Yet, some workers may still find them uncomfortable or restrictive. This raises questions about the balance between protection and daily wearability. Emphasizing the importance of reflective workwear can lead to improved safety standards and fewer workplace incidents.

Definition of Reflective Workwear and Its Key Features

Reflective workwear is specialized clothing designed to enhance visibility in various working environments. It features reflective materials that catch light, making the wearer stand out. This is particularly vital for those working in areas with low light or heavy traffic, such as construction sites or road maintenance. The primary purpose is to reduce the risk of accidents and ensure safety.

Key features of reflective workwear include high-visibility colors like fluorescent yellow or orange. These colors are easily seen during the day. The reflective strips found on these garments reflect light when illuminated, which is crucial at night. Additionally, many designs incorporate breathable fabrics for comfort. Workers stay cool and safe, even during long hours on the job.

Tips: Ensure that your reflective workwear fits well. Loose clothing can hinder movement and may not provide adequate visibility. Regularly inspect your gear for wear and tear. Faded or damaged reflective strips lose their effectiveness. Remember, safety should always be a priority in any work environment. Missing these details could lead to serious consequences.

The Importance of Visibility in Hazardous Work Environments

In hazardous work environments, visibility is crucial. According to the Bureau of Labor Statistics, nearly 20% of workplace fatalities occur in construction, manufacturing, and transportation. Employees in these sectors often face poor visibility. Reflective workwear can help mitigate risks in these settings. This type of clothing reflects light, making workers easily seen by equipment operators and others nearby.

Research from the Center for Disease Control highlights that high-visibility clothing can reduce the likelihood of accidents by up to 40%. However, not all reflective gear is created equal. Some materials may wear down, losing their effectiveness. Poor maintenance can render even the best workwear inadequate. Workers must regularly check their gear for signs of damage.

Situations can arise where the use of reflective clothing is overlooked. Sometimes, workers prioritize comfort over safety. But this decision can lead to disastrous consequences. The role of visibility should never be underestimated. It’s not just about style; it’s about survival in high-risk environments.

Reflective workwear is not merely a requirement. It represents a commitment to safety that should be embraced by every worker. Awareness, proper gear, and ongoing maintenance form a trifecta for reducing accidents on the job.

Types of Reflective Materials Used in Workwear

Reflective workwear plays a critical role in occupational safety. The choice of reflective materials is central to its effectiveness. There are various types of materials used, each with unique properties. Some are designed for high visibility, while others focus on comfort and flexibility.

Commonly used materials include retroreflective tape and fluorescent fabrics. Retroreflective tape reflects light back to its source, enhancing visibility. According to industry studies, wearing garments with retroreflective features can reduce accident rates by up to 50%. Fluorescent fabrics work best in daylight conditions, improving visibility in dimly lit environments.

The fabric choice can also impact worker comfort. Some softer reflective materials offer breathability, but may not provide the same level of visibility. It’s important to find a balance. Workers need to feel comfortable yet seen. A report from the National Institute for Occupational Safety and Health indicates that around 30% of workplace accidents occur in low-light areas. These staggering numbers highlight the importance of choosing the right materials in reflective workwear to ensure safety on the job.

Regulations and Standards Governing Reflective Workwear

Reflective workwear is crucial for safety in various work environments. It helps workers remain visible, especially in low-light conditions. Regulations and standards ensure that this gear meets specific safety requirements. Organizations must comply with these rules to protect their employees.

In many regions, protective clothing standards are set by governing bodies. These guidelines specify the type, color, and placement of reflective materials. Compliance is not just about following rules; it’s about human lives. Many workplaces still struggle with effective implementation. Some workers may not wear reflective gear correctly, undermining its purpose.

Regular training sessions can help address these gaps. Workers should understand the risks they face. They must know how to wear their reflective gear properly. Additionally, employers need to review their policies consistently. Monitoring compliance can significantly reduce accidents in hazardous environments. Reflective workwear is only effective if everyone prioritizes safety.

Best Practices for Choosing and Maintaining Reflective Workwear

When choosing reflective workwear, consider visibility and comfort. Bright colors and retroreflective materials are key. Workers should be seen, especially in low-light conditions. Fit matters. Loose clothing can catch on equipment. Tight clothing may restrict movement. Each worker has different needs, so one size does not fit all.

Maintaining reflective workwear is equally important. Regular washing helps maintain visibility. Follow specific care instructions to avoid fading. Inspect clothing for wear and tear often. Replace items that are no longer effective. Regular checks keep safety standards high but can be easily overlooked.

Reflective workwear can also become a personal reflection of safety culture. Workers may feel empowered wearing it, but it requires commitment. Encourage open conversations about its importance. Listening to feedback from staff helps improve safety practices. Embrace a proactive approach to ensure everyone understands its role.