How to Choose Enameled Aluminum Magnet Wire for Your Projects?

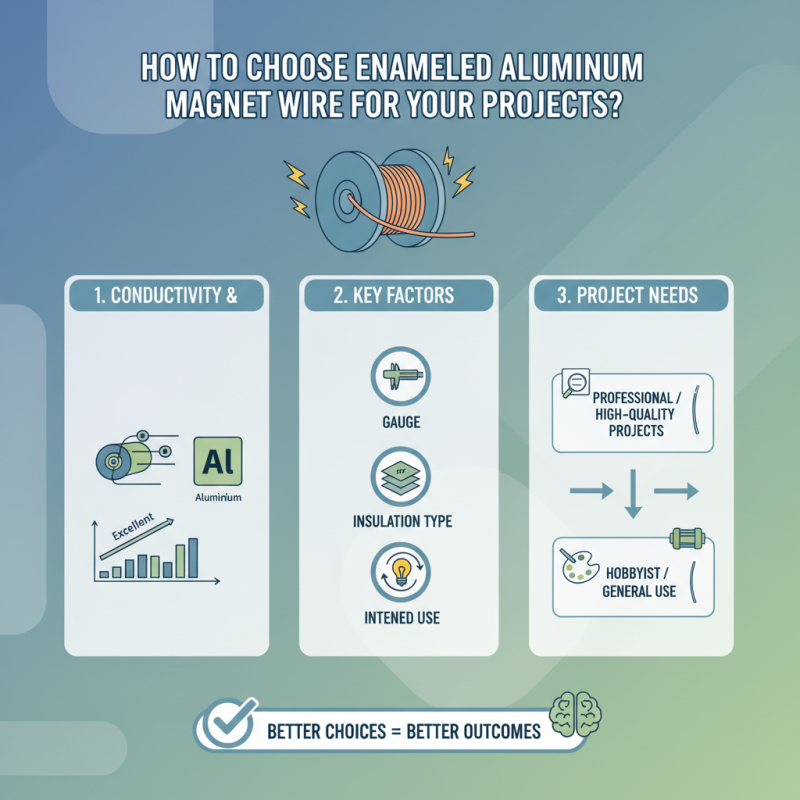

Choosing the right materials for your projects is crucial. Enameled Aluminum Magnet Wire is a popular choice among DIY enthusiasts and professionals alike. This wire offers excellent conductivity, making it ideal for various applications.

When selecting Enameled Aluminum Magnet Wire, several factors come into play. You need to consider the wire's gauge, insulation type, and intended use. Each project has its specific requirements, and matching the wire to those needs can be challenging. Sometimes, the wrong choice can lead to suboptimal results.

Moreover, not all projects may require the best quality wire. For hobbyists, a lower gauge might suffice. Reflecting on your project goals can help you make better decisions. Ultimately, understanding Enameled Aluminum Magnet Wire will enhance your outcomes and improve your overall project experience.

Factors to Consider When Selecting Enameled Aluminum Magnet Wire

When selecting enameled aluminum magnet wire, several factors warrant careful consideration. The wire's insulation type is crucial. Different insulation materials offer various thermal ratings. Selecting the right type can greatly affect performance. For instance, a typical rating ranges from 130°C to 220°C. Higher rated options may be necessary for intense applications.

Conductor size is another significant factor. The American Wire Gauge (AWG) standard helps you choose the appropriate diameter. A smaller gauge may carry more current, but it also adds weight. It’s important to balance these aspects. According to industry reports, using a wire with a larger gauge in low-efficiency motors can lead to up to 15% energy loss.

Winding techniques also play a role. Some techniques require specific wire characteristics. Interlayer insulation might be necessary for larger coils. Frequent mistakes include underestimating the mechanical properties of the wire. Data indicates that improper selection can decrease longevity and lead to faults. Knowing the mechanical flexibility and tensile strength is vital for long-term reliability.

Types of Enameled Aluminum Magnet Wire and Their Applications

When selecting enameled aluminum magnet wire, understanding the various types is crucial. Each type offers distinct properties that suit different applications. For example, there are several insulation classes, ranging from Class 105 to Class 220. Class 155 wires are popular in consumer electronics, while Class 180 is often used in industrial motors. Each class has its heat tolerance level, affecting overall performance.

In applications requiring flexibility, it's wise to consider the variety that offers higher tensile strength. This durability is essential for winding and crafting coils. Some wires come with superior abrasion resistance, making them suitable for harsh environments. However, cost can be a significant factor; high-performance options tend to be pricier.

It's also important to reflect on the environment where the wire will be used. Factors like humidity and exposure to chemicals should be considered. If the project has specific requirements, not all types of enameled aluminum magnet wires will suffice. Careful thought is necessary to avoid potential failures. Selecting the right type ensures longevity and efficiency in any project.

Understanding Wire Gauge and Its Importance in Enameled Aluminum Wire

When choosing enameled aluminum magnet wire, understanding wire gauge is crucial. Wire gauge refers to its thickness. Thicker wires carry more current. However, thinner wires are easier to work with. Each project may require a different gauge. It's essential to know the specifications of your project.

For example, a transformer might need a specific gauge to operate efficiently. If you choose the wrong gauge, you might face overheating or underperformance. In this case, experimenting with different gauges often leads to valuable lessons. You'll discover that what works for one application may not suit another.

Selecting the right wire gauge can be tricky. Some choices might seem perfect at first. But, after testing, they may fail to meet your expectations. Always consider the balance between flexibility and conductivity. A trial-and-error approach can lead to insights. Don't shy away from re-evaluating your choices for better results.

How to Choose Enameled Aluminum Magnet Wire for Your Projects? - Understanding Wire Gauge and Its Importance in Enameled Aluminum Wire

| Wire Gauge | Diameter (mm) | Current Carrying Capacity (A) | Applications |

|---|---|---|---|

| 18 AWG | 1.024 | 10 | Small transformers, motors |

| 20 AWG | 0.812 | 8 | Solenoids, coils |

| 22 AWG | 0.644 | 6 | Windings, small speakers |

| 24 AWG | 0.511 | 3.5 | Speakers, RF coils |

| 26 AWG | 0.405 | 2.5 | Hobby projects, sensors |

Evaluating the Insulation Properties of Enameled Aluminum Magnet Wire

When selecting enameled aluminum magnet wire, understanding the insulation properties is crucial. The insulation quality directly affects the wire's durability and performance. Proper insulation prevents short circuits and ensures longer life in demanding applications. Thick insulation can provide excellent protection, but it may also reduce flexibility. This trade-off must be evaluated based on specific project requirements.

Different insulation types offer varying benefits. Some insulations withstand higher temperatures, enhancing performance in heat-sensitive environments. Others may be better for environments with moisture or chemicals. Testing insulation in real-world conditions can reveal unexpected weaknesses. You might find that an ideal choice on paper doesn't perform well in practice.

Inevitably, the decision involves compromise. A thicker coating might not always fit into tighter spaces. An overly rigid wire can be challenging to handle and install. It’s essential to consider these factors carefully. Testing different wires in small-scale projects may help identify the best choice. Consider revisiting your findings regularly as new materials and techniques emerge.

Tips for Testing and Validating Enameled Aluminum Wire Quality

When selecting enameled aluminum wire, quality is paramount. You want to ensure it meets your project requirements. Start with visual inspection. Look for any visible defects in the enamel coating. It should be uniform and free from cracks or bubbles. Minor flaws can impact performance.

Next, conduct a conductivity test. Utilize a multimeter to check the wire's electrical resistance. The resistance should fall within acceptable ranges for your specific application. If it doesn't, consider the wire's suitability. A simple pull test can also provide insights. Ensure the wire adheres well to the enamel insulation. Poor adhesion can lead to short circuits in critical applications.

Consider thermal resistance as well. Heat can degrade quality over time. Test the wire under elevated conditions and monitor how it behaves. Look for changes in flexibility or any discoloration. These factors are essential for long-term success. Proper testing can save future complications. Quality control is crucial, and making adjustments based on your findings is necessary for optimal performance.