How to Choose the Best Stainless Steel Woven Wire Mesh?

Choosing the right stainless steel woven wire mesh can be a daunting process. The market offers a diverse array of products, each designed for specific applications. According to a recent industry report by Research and Markets, the stainless steel mesh market is projected to grow at a CAGR of 4.5% through 2026. This growth highlights the increasing demand for durable and versatile materials in various sectors, including construction and filtration.

Expert John Mitchell, a leading authority in metal mesh applications, emphasizes that "the right mesh selection is crucial for achieving optimal performance." His insight reflects the significance of understanding mesh grades, wire diameters, and weave patterns. These factors can dramatically affect results, yet many buyers overlook them. While choosing stainless steel woven wire mesh, consider both your short-term and long-term needs.

The challenge lies in balancing quality with cost. Many manufacturers cut corners, leading to inferior products. Poor quality mesh can fail under stress or corrode quickly, making it crucial to carefully evaluate suppliers and their offerings. Ultimately, thorough research and expert advice can prevent costly mistakes.

Understanding Stainless Steel Woven Wire Mesh Types and Specifications

Choosing the right stainless steel woven wire mesh requires understanding its types and specifications. There are various grades of stainless steel, including 304 and 316. Grade 304 is versatile, while 316 has superior corrosion resistance. For high-temperature applications, select a mesh that can withstand heat without compromising strength.

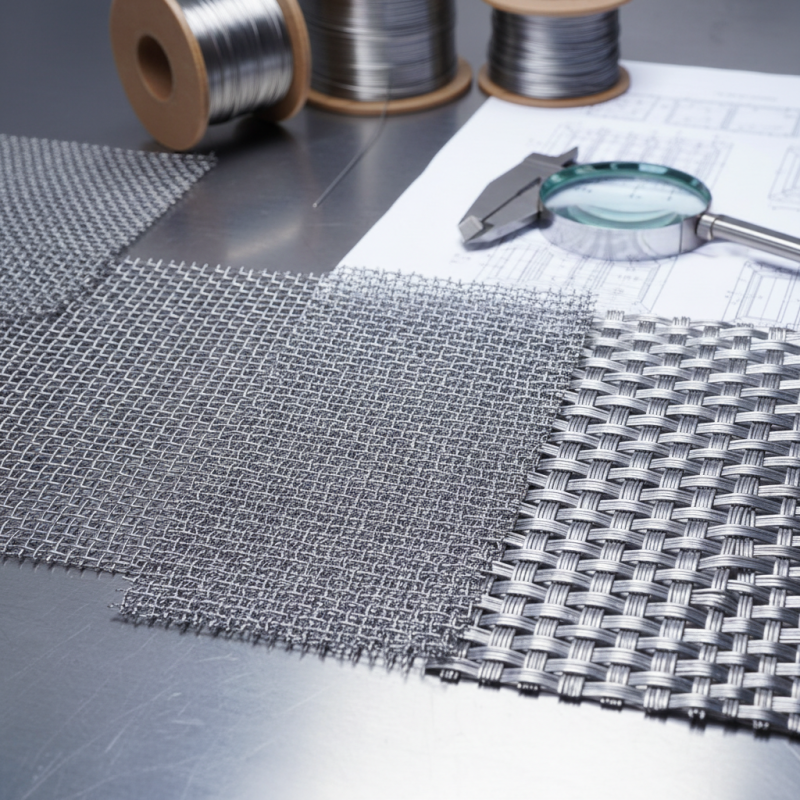

When looking at mesh specifications, consider the opening size and wire diameter. The opening size impacts filtration efficiency. A smaller opening can filter finer particles, but it may reduce airflow. Wire diameter also affects tensile strength. Thicker wires are generally sturdier but can be heavier.

Tips: Measure the space available for installation. Always account for tolerance in your measurements. Inspect the mesh closely for any signs of damage. Small flaws can lead to bigger problems later. Test samples before making a bulk purchase. This ensures the mesh meets your requirements.

Key Factors to Consider When Selecting Stainless Steel Wire Mesh

When selecting stainless steel woven wire mesh, several key factors should guide your decision. The mesh's weave pattern affects both strength and flexibility. Twill weave offers durability, while plain weave provides better filtration. You need to consider the application for which you'll use the mesh. For instance, filtration uses require finer mesh sizes, while protective barriers demand larger openings.

Additionally, the stainless steel grade matters significantly. Different grades offer varying corrosion resistance and strength levels. For environments exposed to harsh chemicals, a higher grade is essential. You should also reflect on the wire diameter. Thicker wires increase strength, but they may limit flexibility. Think about how much weight the mesh must support over time.

Don't overlook the mesh's width and length. Custom sizes may be necessary. Adjusting measurements can introduce complications. If you choose a standard size, ensure it fits your application precisely. Miscalculations can lead to wasted materials. Each of these factors plays a pivotal role in achieving the desired performance from your stainless steel woven wire mesh.

Evaluating Mesh Opening Sizes for Your Specific Application Needs

When choosing stainless steel woven wire mesh, evaluating mesh opening sizes is crucial. Different applications require different wire sizes to achieve optimal performance. For instance, the food and beverage industry often uses mesh with openings that are 1/4 inch or smaller to ensure hygiene and product quality. A recent industry report highlighted that 70% of companies prefer this size for filtration purposes. Smaller openings help prevent contamination while maintaining efficient flow.

In contrast, industrial applications might require larger openings. Mesh with 1/2 inch to 1 inch openings provides necessary support for heavy materials. However, using a size too large can lead to premature wear or structural failure. A survey showed that 35% of engineers considered opening sizes as a leading factor in material selection. Thus, proper evaluation is essential, as overlooking this can result in costly mistakes.

One common mistake is assuming larger openings mean less resistance. This isn't always true. The weave pattern also influences performance. Simplistic designs may seem easier to work with, yet they can fail under certain loads. Understanding your specific needs before making a decision is vital. This ensures the mesh chosen will perform optimally and last longer.

Identifying the Right Stainless Steel Grade for Durability and Performance

Choosing the right stainless steel grade is crucial for woven wire mesh. Different grades offer unique properties. For instance, 304 stainless steel is often used for its good corrosion resistance. It is common and versatile. However, in harsher environments, you might face limitations.

Consider 316 stainless steel for better durability. It contains molybdenum, enhancing its resistance to chloride exposure. This makes it ideal for marine settings. Knowing your environment helps in selecting the appropriate grade. You might think 304 is enough, but it can fail under stress.

When evaluating your needs, think about long-term performance. Are there specific temperatures or chemicals involved? Any oversight here could lead to premature wear. Pay attention to the details of your application. Sometimes a minor change in grade can drastically affect outcomes. Take the time to reflect on your choices.

Comparing Cost-Effectiveness and Quality in Stainless Steel Wire Mesh Options

Choosing the right stainless steel woven wire mesh involves a careful balance between cost-effectiveness and quality. Stainless steel mesh can vary widely in price and performance. It's essential to consider the intended application. Are you using it for filtration, fencing, or industrial components? Each application has unique demands.

Cost is often a primary concern. However, opting for the cheapest option may lead to compromises in quality. Some lower-grade meshes may rust or degrade quicker, leading to increased replacement costs. Investing in a quality mesh might save you money in the long run, but it requires upfront budget flexibility.

Quality also encompasses the manufacturing process. Variances in weaving techniques impact durability and functionality. A poorly woven mesh may lack the necessary strength or precision. It's important to scrutinize these details. When evaluating options, ask about production methods and materials used. A small oversight could lead to significant issues later on. Balancing costs and quality is complex. Take your time to consider all factors critically.