What is a Ball Bearing and How Does it Work?

Ball Bearings are vital components in modern machinery. They reduce friction and wear in rotating parts. According to a report by MarketsandMarkets, the global ball bearing market was valued at USD 41.4 billion in 2021. This figure is projected to reach USD 54.2 billion by 2026. Such growth highlights the importance of ball bearings in various industries, from automotive to aerospace.

The efficient operation of ball bearings significantly influences machinery performance. These components allow for smoother motion, increasing lifespan and reliability. However, not all ball bearings perform equally. Factors like material quality and design can affect their effectiveness. Misunderstandings about their specifications can lead to poor machinery performance. Engineers must carefully evaluate bearings to meet specific needs.

Ball bearings support critical functions in countless devices. Yet, the design and selection process can be overlooked. This neglect may cause failures and unexpected repairs. Recognizing the true value of ball bearings is crucial for optimizing operations. Understanding their function is essential for any industry reliant on rotating equipment.

What is a Ball Bearing?

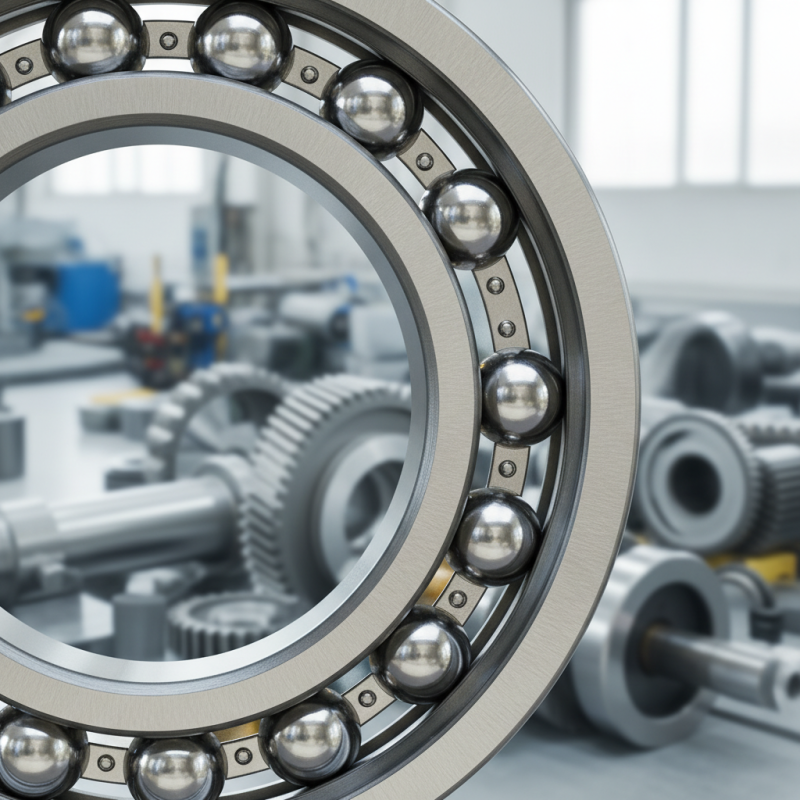

Ball bearings are essential components in many machines. They reduce friction between moving parts, allowing smoother operation. The basic design consists of a series of balls situated between two rings, known as races. When one ring rotates, the balls roll, minimizing contact and friction.

According to a recent industry report, the ball bearing market size is projected to reach $20 billion by 2025. This growth is driven by increasing demand in automotive and industrial applications. However, not all ball bearings are created equal. Factors such as material quality and design can significantly impact performance. In some cases, low-quality bearings can lead to premature failure, resulting in costly downtime.

Many engineers overlook maintenance for ball bearings. Regular inspection is crucial. A contaminated bearing can lead to a decrease in efficiency. Statistics show that about 42% of bearing failures stem from lubrication issues. This highlights the need for systematic checks and timely interventions. While advancements in technology improve bearings, the basics remain unchanged. Observing traditional practices is still vital for optimal performance.

What is a Ball Bearing and How Does it Work?

| Dimension | Measurement | Material | Common Applications |

|---|---|---|---|

| Inner Diameter | 5 mm - 100 mm | Steel | Electric Motors |

| Outer Diameter | 10 mm - 150 mm | Stainless Steel | Automobiles |

| Ball Diameter | 3 mm - 50 mm | Ceramic | Aerospace |

| Load Capacity | Up to 8000 N | Polymer | Industrial Machinery |

| Speed Rating | Up to 60,000 RPM | Chrome Steel | Sports Equipment |

History and Evolution of Ball Bearings

The history of ball bearings is rich and fascinating. They date back to ancient civilizations. The earliest known use was in the Roman era, where wooden bearings were employed. These primitive designs limited efficiency and durability. Over the centuries, advancements have transformed ball bearings into precision-engineered components.

In the late 19th century, industrialization drove demand for better bearings. In 1869, an innovative design emerged, featuring steel balls between two races. The new system reduced friction significantly. According to a 2021 study by the International Association of Engineering, modern ball bearings can decrease energy consumption by up to 30%. This notable improvement impacted various industries, from automotive to aerospace.

Despite advancements, issues still arise. Manufacturing defects can lead to early failure in ball bearings. A report from the Bearing Industry Association highlighted that 25% of early failures stem from misalignment. Furthermore, while new materials enhance performance, they also require careful handling. Balancing innovation with quality control remains a challenge for manufacturers today.

Components of a Ball Bearing and Their Functions

A ball bearing is a crucial mechanical component composed of several key parts. At the core are the balls themselves. They are typically made from steel, ceramic, or plastic. These balls enable smooth rotation and reduce friction. They sit between two races, which are the inner and outer rings. These rings create a housing for the balls to function efficiently.

Another essential component is the cage or separator. This part keeps the balls evenly spaced. It prevents them from clashing with each other. The cage significantly enhances the bearing's longevity and performance. Lubrication is also vital for a ball bearing. It minimizes wear and tear during operation. Oil or grease fills the space between the balls and their races.

Despite its simple design, ball bearings can sometimes fail. Factors like incorrect installation or insufficient lubrication often lead to issues. Users must regularly maintain ball bearings to ensure optimal performance. It’s easy to overlook these details, but they are critical for effectiveness. Even a small error in handling can cause premature wear. Therefore, attention to detail is important whenever dealing with these components.

How Ball Bearings Reduce Friction and Wear

Ball bearings play a crucial role in reducing friction and wear in various machinery. They are designed to support rotational motion by minimizing contact between moving parts. According to a report by the American Society of Mechanical Engineers (ASME), effective use of ball bearings can reduce friction by up to 80%. This significant reduction contributes to enhanced efficiency and longevity of equipment.

The key to their function lies in their design. Ball bearings consist of steel balls housed within a circular race. This arrangement allows for smooth rotation and minimal resistance. When a shaft turns, the balls rotate between the inner and outer race, creating a thin layer of lubrication. This layer decreases direct metal-to-metal contact, thereby reducing wear. A study from the International Journal of Mechanical Sciences indicates that using lubricants can enhance the lifespan of ball bearings by up to 300%, yet many overlook this critical factor in maintenance.

However, not all ball bearings operate perfectly under all conditions. Environmental factors like temperature and contamination can undermine their efficiency. In some cases, improper installation or misalignment can cause premature failure. Regular monitoring is essential, yet many manufacturers fail to prioritize this aspect. Such oversights highlight the need for a deeper understanding of ball bearing maintenance and performance.

Applications of Ball Bearings in Various Industries

Ball bearings are essential in various industries. They reduce friction between moving parts. This allows machinery to operate smoothly and efficiently. In manufacturing, ball bearings play a crucial role. They enhance the performance of conveyor systems. Without them, production rates could significantly slow down.

In the automotive industry, ball bearings support engine components. They help wheels rotate seamlessly. Proper functioning is vital here; otherwise, wear and tear can increase. In aerospace, they take on even more significance. High precision is key for safety and reliability. Yet, even the best ball bearings can fail. Regular maintenance is essential to avoid unexpected breakdowns.

In the electronics sector, ball bearings are used in hard drives and fans. They improve performance and prolong the life of devices. However, their tiny size can lead to big challenges. Overheating or contamination can cause malfunctions. Understanding the needs of each application is critical. This ongoing process often presents room for improvement.